(THIS ARTICLE IS MACHINE TRANSLATED by Google from Norwegian)

Perhaps you've heard of it – perhaps you even saw it barely mentioned in the previous MODERN TIMES (Anders Dunker on Monbiot and topsoil)? There is one Finnish company in particular that has reached the media in recent years with its "food from thin air" project. But where does this one come from? foodone from, yes, besides from air? The idea is not that new at all; this has been on NASA's plate since the 1960s, but has only recently been further developed into a finished product.

It takes an incredible 15 liters for 000 kg of beef – Air Protein only uses 1 liters of water to produce 0,8 kg of proteins.

In the 60s discovered NASA at photosynthesisn that the plant grows and can become food: carbohydrates, protein and oxygen. But the "air proteins" are approximately 20 times more efficient than normal photosynthesis.

US Kiverdi started in 2008 with further development of NASA's ideas, and in 2019 they founded Protein Water, which is also the name of the product. Kiverdi and Air Protein were founded by Dr. Lisa Dyson and Dr. John Reed.

And Finnish Solar Foods calls its protein product Solein. Five Finnish researchers started up in 2017 after research had been carried out by the state-owned research center VTT Technical Research Center of Finland and Lappeenranta-Lahti University of Technology (LUT). And there are several companies out there, such as NovoNutrients and Orbital Farm.

Carbon negative process

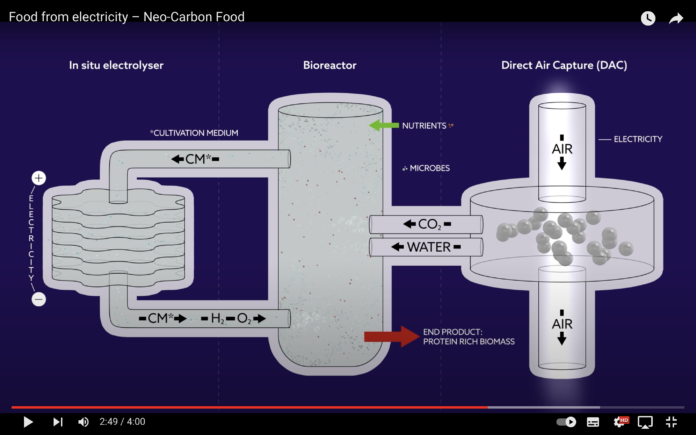

The process can be done on both a small and large scale and is carbon negative as long as it is based on renewable energy. Here, there is no need for large areas to be cultivated, animals to be fed, washed and looked after – all with high CO2-impression. Only a small production room is needed – which is fed, among other things, with CO2, taken from the air. It can be done at the North Pole, in the Sahara or on a deserted island – or in a spaceship.

Food production today is among the worst in terms of land use, water consumption and not least CO2-emissions and is considered to make up a third of the world's CO2- emissions. 80 percent of this again comes from meat production. And it is precisely here that air food has its biggest advantage – less CO2, for CO2 is the main ingredient, and with renewable energy for production is the entire process karbonnegative. Also when it comes to land use, it has a huge advantage. For one kilogram of Solein protein, 1 square meter is needed, compared to plants' approx. 20 and beef approx. 200 square meters. Dyson also emphasizes that their air protein has several other health benefits compared to animal meat. The substance does not contain soy, hormones, pesticides, herbicides or genetically modified organisms. It is more protein-rich per kilogram than any meat and rich in vitamins, minerals and amino acids.

Minerals such as phosphorus, sulphur, calcium, iron and potassium are added to water so that it ferments, not unlike how you brew beer, for example. You then dry out the water and end up with a powder which, among other things, consists of 65 percent protein, 5 percent fatty acids and 15 percent digestible fibers and some minerals. The end product is mustard yellow and flour-like – and neutral in taste. This must be able to be added to already existing products, whether it is pancakes, pasta or sauce. While Solar Foods manufactures protein powder, Air Protein makes its own finished chicken-like product – Air Meat. It is claimed that both Air Protein and Solein can be made in just a few days.

The potential is great, but at the same time there are many regulations. Currently, only Singapore has allowed the sale of such protein, from Finnish Solar Foods. It happened recently, in September this year.

Increase in food production?

According to the UN and the Food and Agriculture Organization (FAO), we need to increase food production up to 2050 by up to 60 per cent.

A third of food production is wasted.

But they also say: "We must work in ways to feed the world with less." Eating out of thin air fits well in such a thought, but it is not the only solution, and it is important to keep all possibilities open. Food waste is still something we should be aware of, especially in the industrialized countries, where the waste is greatest. Globally, we produce more than enough food for everyone, somewhere between 10 and 12 billion people. But a third of food productionone goes to waste. Europe and the USA are the worst, with respectively 95 and 115 kg of annual waste per consumer. In sub-Saharan Africa and South/South-East Asia, wastage is much lower, with 6 to 11 kg per consumer per year.

Air Protein makes its own finished chicken-like product – Air Meat.

If we manage to reduce wastage by just 25 per cent, that in itself could be enough to feed 500 million people and reduce the need for growth in food production.

In the big picture, it is also necessary to include water and water consumption. Groundwater is a non-renewable resource (only 6 percent is renewable), and we as humans have taken a facile view of water as something that is "just there". While it takes approximately 1350 liters of water for 1 kg of wheat and 3000 liters for 1 kg of rice, it takes an incredible 15 liters for 000 kg of beef. Air Protein uses only 1 liters of water to produce 0,8 kilogram of protein – and is in a class of its own. Alongside the enormous water consumption, agriculture and animal husbandry also contribute to contaminating the groundwater, thus a complete vicious circle.

Future food such as laboratory meat and insects

Can we then conclude that aerial protein is a winner? Both yes and no. This is not the only new "food of the future". Laboratory produced meat is another relatively new solution, but perhaps has an unfortunate "yak" problem that makes it inedible, but with time and not least lack of food, that can quickly turn around. Singapore is also the only country to allow lab-grown meat, with Eat Just's cultured 'chicken'. "No animal was killed during this process" may become the slogan, but many people still frown at the fact that it is laboratory meat. Based on DNA, i.e. a kind of live-dead meat production. Almost like a cow or chicken- plants.

Although both lab meat and air proteins are becoming competitive in price, they must be approved for sale. And while these products may soon be competitive in price for the wealthy North, it will probably be a long time before they become so in the global South. It is therefore important to have a broad view of the food of the future and adapt it to the conditions. Indoor, hydroponic vertical cultivation with LED lights will certainly also become more relevant unless electricity prices skyrocket. It will be able to produce nutritious and short trip food. By way of comparison, 1 square meter of land use here corresponds to 125 square meters in ordinary agriculture.

Other places on the globe possibly will insectis becoming more popular. While some develop lasers to take the rat on cockroaches, others drift cockroachfarms due to the cockroach's nutritional content. It is mostly used for animal feed, but is actually also considered a delicacy for humans. While it might slip under the label as "proteins from insects", the cockroach declaration will probably also have a high "yak factor".

A couple of centuries ago, blue-green algae – especially chlorella and spirulina – had the same hype as air proteins have today. They have an enormously high nutritional content and are easy to grow. They are usually grown in shallow ponds and require little else than sun, heat and labour. They are not as water efficient as air proteins, and although the price is decreasing, it is still too high for many. Here, too, new techniques are being developed to reduce production costs.

Finance

Air proteins will certainly find their place on our dinner table. Both Air Protein and Solar Foods has received millions in funding, the latter among others from the European Space Agency (ESA). While Air Protein has managed to raise 32 million dollars, the Finns have raised a total of 42 million dollars, so the possibility is that we will see these products for sale, also here in Norway.